Baysoon BN-302Li 12 Inch DTF Printer For Sale

The high cost-effective and stable performance of the 30cm DTF printer, with optional F1080 and I3200 print heads and low startup cost, is a good choice of many business starters.

- Printhead : I3200 / F1080

- Head Qty: 2

- I3200 Print Speed : 4pass:9m²/h , 6pass:6m²/h

- F1080 Print Speed : 4pass:4m²/h , 6pass:3m²/h

- Max Print Width : 300mm

- Printing Color : CMYKW

- Power Voltage : 110V/220V

- RIP Software : Maintop 6.1 / Photoprint / PF / CADlink

DTF Printer Video

DTF Printer features

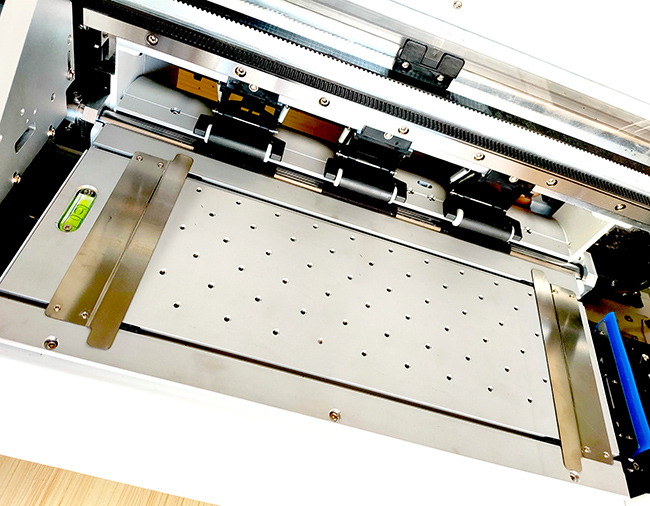

Level measuring instrument

Equipped with a level detector to detect whether the machine is in a level state, which can be adjusted through foot support

Intelligent Sprinkle Dryer

Intelligently detects the temperature and humidity of the powder shaking machine, and adjusts the powder amount according to needs to ensure stable and reliable printing quality and improve production efficiency.

White ink circulation stirring

The white ink is continuously and evenly stirred to prevent precipitation in the white ink and ensure that the printed images are clear and colorful.

Automatic take-up system

The release and recovery of wires are precisely controlled through the motor drive, which reduces the time and steps of manual operations and improves the overall efficiency of printing work.

BN-302Li DTF Printer parameters

| Product | DTF printer |

| Model | BN-302Li |

| Printhead | I3200/F1080 |

| Head Qty | 2 |

| I3200 Printing Speed | 4PASS: 9m²/h, 6PASS: 6m²/h |

| F1080 Printing Speed | 4PASS: 4m²/h, 6PASS: 3m²/h |

| Print Media | PET film |

| Printing Color | C M Y K W |

| Max Print Width | 300mm |

| Print Media | PET film |

| Ink Type | DTF pigment ink |

| Transmission Interface | Gigabit Network Port transmission |

| Media width | 300mm |

| Head Height | Adjustable height 0-12mm |

| Power Voltage | 220V/110V |

| Ink Supply System | 0.5L ink bottle with alarm function white ink agitate and circulation |

| RIP Software | Maintop 6.1、Photoprint、PF 、CADlink |

| File Format | PDF, TIFF, JPEG, etc. |

| Machine Size | Printer: 970*540*450mm; shaker: 900*600*580mm |

| Packing Size | Printer: 1080*650*660mm, 75KG ; shaker: 800*610*710mm, 45KG |

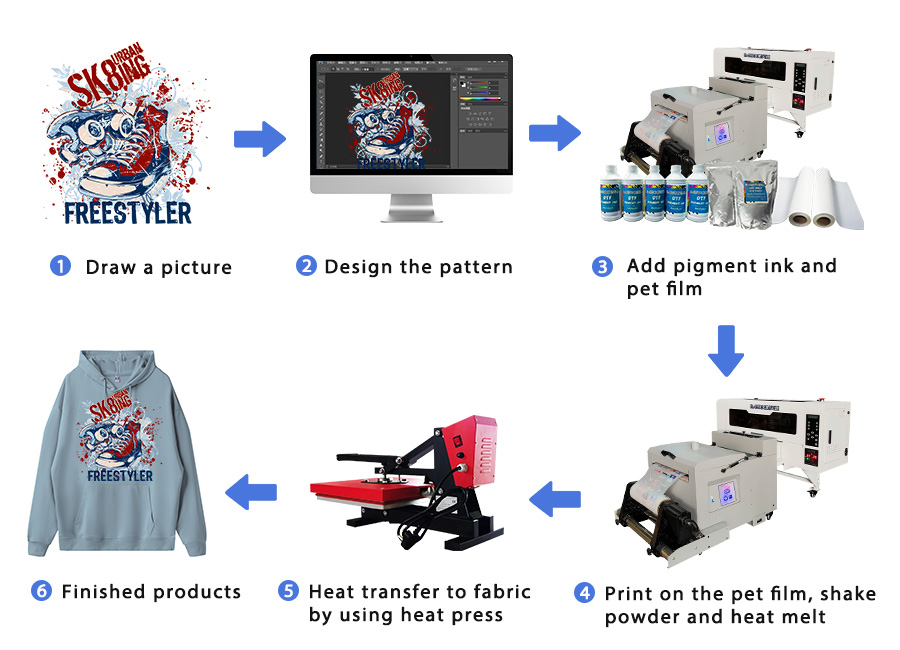

DTF Printer working process

DTF Printer Applications

Suitable for printing on various clothing materials, including cotton, polyester, nylon, treated leather, polyester fabrics, 50/50 blends, and light and dark fabrics. At the same time, it can also be applied to different types of surfaces, such as luggage, shoes, canvas, etc.

Related Consumables

DTF ink

DTF PET film

hot melt powder

Hot pressing machine

Related products

BN-602X DTF printer

BN-602Li DTF printer

BN-604Li DTF printer

BN-605Li DTF printer

FAQ

DTF printer, or “direct to film printer”, is a process equipment used in the clothing industry. It uses high-temperature transfer technology to print computer-designed patterns on various fabrics. This printing method is environmentally friendly, has fast printing speed, and stable quality.

DTF (direct-to-film) printing technology is suitable for almost all types of fabrics, such as cotton fabrics, polyester, nylon, denim, linen, and so on.

DTF technology is suitable for almost all types of fabrics. Including cotton, linen, silk, polyester fiber, etc.

DTF technology first prints the pattern on a special PET film and then transfers the pattern from the PET film to the textile through thermal transfer. It has good durability and is not easy to fall off or fade.

DTG technology prints ink directly on textiles and is more suitable for cotton and blended fabrics. The printed pattern is soft and has good breathability and hand feel.

DTF has higher production efficiency than DTG and can achieve mass production.

DTF contrasts screen printing without the need for plate making and enables fast, efficient and high-quality printing through digital technology.

If you need to achieve personalized customization, high-quality printing, rapid production and multi-color printing, DTF may be more suitable.

If you’re more focused on durability, color vibrancy, and cost-effectiveness, then vinyl printing may be better for you.

The printing cost for 1 sqm transfer fabric pattern is approximately $1-2.

It requires PET film, DTF ink, and hot melt powder to be used together.

Yes. Just let us know your local voltage and plug standard, we can supply 110V and 220V.

Comprehensive printing services

One-stop printing solution

We provide various printing solutions, including printer, ink, PET film, AB film, hot melt powder and other consumables, making printing worry-free!

free print samples

In order to demonstrate the quality and performance of our printers and to meet your needs, we can provide you with free print samples.

Technical Training

You can communicate with our professional technicians in real time through WeChat or Whatsapp to solve various problems encountered during the use of the printer.

Fast delivery

After you place an order, we will ship it as soon as possible, usually within 3-5 days, allowing you to experience high-quality printing services as soon as possible.

Lifetime service & one year maintenance

One-year warranty for the main parts of the machine, lifetime service for the whole machine, free after-sales consultation, etc.

start your business

do it better

your one-stop serivce provider which will simplify your business