What is a DTF Printer?

The world of fashion and textiles is constantly evolving, and technology plays a significant role in this evolution. One such technological advancement that has gained popularity in recent years is the Direct-to-Film (DTF) printer. But, have you ever wondered what a DTF printer is and how it works? In this blog, we will delve into the world of DTF printing, exploring its benefits, applications, and everything else you need to know.

What is a DTF Printer?

A DTF (Direct-to-Film) printer is a digital printing machine designed specifically for printing on fabrics. Unlike traditional screen printing methods, which require creating a stencil or plate for each color, DTF printing uses specialized inkjet technology to directly apply ink onto the fabric. This process allows for faster production times, greater flexibility, and increased cost-effectiveness.

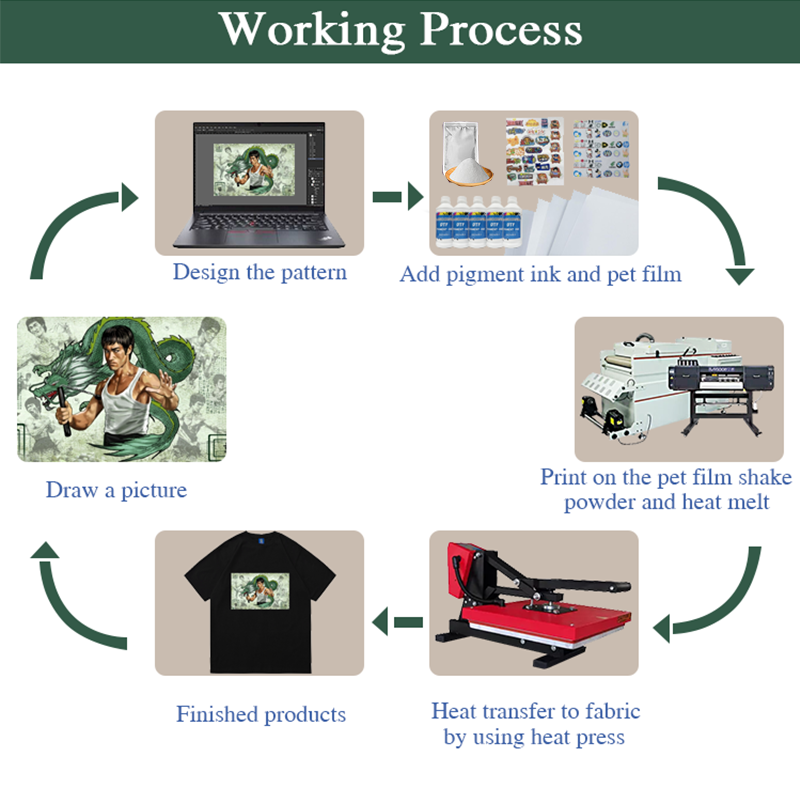

How Does A DTF Printer Work?

The DTF printing process begins with a digital file, which is sent to the printer using specialized software. The printer then reads the file and applies the appropriate amount of ink to the fabric, carefully controlled by advanced algorithms and precision mechanical components. The ink is applied in layers, allowing for intricate details and color gradients. Once the printing process is complete, the fabric is heat-cured to fix the ink and ensure durability.

Benefits of DTF Printing:

One of the most significant advantages of DTF printing is its ability to produce small batches or even single pieces efficiently and cost-effectively. Traditional screen printing requires large minimum order quantities and lengthy setup times, making it impractical for small runs. DTF printing eliminates these limitations, enabling designers and manufacturers to produce limited edition collections, samples, and prototypes with ease.

Another benefit of DTF printing is its versatility when it comes to fabric types. Unlike screen printing, which is restricted to smooth, flat surfaces, DTF printing can handle a variety of fabrics, including cotton, polyester, silk, and even stretchy materials. This opens up endless possibilities for designers working with different textures and materials.

Applications of DTF Printing:

①DTF printing has numerous applications across various industries, including:

②Fashion: Designers can create unique, custom prints for their collections, giving them an edge over mass-produced garments.

③Sportswear: DTF printing enables the creation of custom sports jerseys, shorts, and other apparel with team logos, names, and numbers.

④Home Decor: Custom printed fabrics can be used for curtains, upholstery, bedding, and wall art, adding a touch of personality to any room.

⑤Promotional Products: Companies can use DTF printing to create branded merchandise such as T-shirts, hoodies, and tote bags.

⑥Art and Design: DTF printing offers artists and graphic designers a new medium for their work, allowing them to create stunning, large-scale prints on fabric.

In conclusion, DTF printing is a revolutionary technology that has transformed the way we produce and interact with textiles. Its efficiency, versatility, and quality make it an attractive option for designers, manufacturers, and entrepreneurs alike. As the demand for customization and sustainability continues to grow, DTF printing is poised to play a critical role in shaping the future of fashion, sportswear, home decor, and beyond. Whether you’re looking to create unique designs, streamline production, or reduce waste, DTF printing offers countless opportunities for innovation and expression.